mechanism of creep of material at high temperature|what is creep resistant to : chain store The creep deformation will be permanent even if the stresses are below yielding point of the material. The effect of creep rapidly increases at elevated temperatures due to an increase in diffusion rate. Soft materials can creep at room temperatures while denser materials creep at elevated temperatures. webGeisy Arruda foi à web nesta quinta (28) mostrar um pouco de seus dotes culinários e, para a ocasião, gravou com Kid Bengala, na Casa das Brasileirinhas - espaço de realities .

{plog:ftitle_list}

WEB11 de set. de 2021 · Rina Palenkova died by suicide in 2015. It is believed that the 17-year-old girl had been participating in the Blue Whale Challenge when she took her own life .

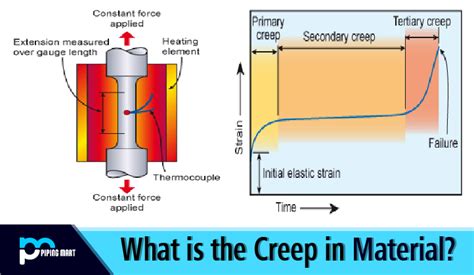

In materials science, creep (sometimes called cold flow) is the tendency of a solid material to undergo slow deformation while subject to persistent mechanical stresses. It can occur as a result of long-term exposure to high levels of stress that are still below the yield strength of the material. Creep is more severe in materials that are subjected to heat for long periods and generally increases a.The creep deformation will be permanent even if the stresses are below yielding point of the material. The effect of creep rapidly increases at elevated temperatures due to an increase in diffusion rate. Soft materials can creep at room temperatures while denser materials creep at elevated temperatures.

Creep is the time-dependent deformation of a material under constant stress at high temperatures. It occurs due to the movement of vacancies and dislocations within a material's microstructure. . The critical . The creep behavior of a novel powder metallurgy (PM) Ni-based superalloy is investigated at temperatures ranging from 760 to 815 °C and stress levels in the 480–620 MPa. . High-Temperature Creep Behavior and Damage Mechanism of an Advanced Powder Metallurgy Ni-Based Superalloy. Xinyu Li, . High Temperature Material Research Institute . In this paper, the AA6111 matrix composites reinforced by in-situ ZrB 2 nanoparticles were fabricated via an Al-Zr-B reaction system and their creep behavior at high temperature was also comprehensively studied. The threshold stress of AA6111-3ZrB 2 composites at 573 K reached to 28 MPa, which was much higher than the only 15 MPa of .

The high-temperature mechanical properties of the IFW joints were systematically analyzed. Under the creep testing condition of 680°C, the specimens exhibited creep fracture at the thermomechanically affected zone (TMAZ) of the PM superalloys. Further, the failure lifetime is enhanced with a reduction in the applied creep loading. The creep properties of sintered nano-silver, which are related to the microstructure evolution, are crucial for the reliability of the packaging structure of wide bandgap semiconductors. In this work, numerical simulations were conducted to investigate the relationship between the creep mechanism and microstructure. Meanwhile, corresponding constitutive .

The constant load creep tests in tension were carried out in argon on all states of materials, at temperatures of 648–723 K and different ranges of applied stresses. From the value of the steady-state creep rate, the control creep mechanisms were determined. The microstructure analyses were carried out via SEM and TEM.

The high-temperature properties of IN625 alloys have been extensively studied, particularly the creep properties. Liu et al. [21] found in the high-temperature tensile and high-temperature creep behavior of IN625 alloy plates that the creep behavior is significantly affected by temperature. At 650 °C, creep is primarily driven by grain .The formula plays a crucial role in material science, particularly in predicting the long-term behaviours of materials subjected to high temperatures and continuous stress. Aerospace, power generation, and automotive industries utilise this equation extensively to determine the creep life of critical components and materials like high . A novel Hf 6 Ta 2 O 17 ceramics is prepared by a solid-state reaction method. High-temperature creep behavior of Hf 6 Ta 2 O 17 and 8YSZ ceramics are investigated by compressive creep test combined with a digital image correlation (DIC) method. It is found that the creep mechanism of Hf 6 Ta 2 O 17 ceramics is controlled by grain boundary sliding .

High-temperature creep tests of additively manufactured (AM) and wrought nickel alloy 718 (IN718) were conducted at 650 °C and 704 °C at stresses ranging from 316 to 819 MPa. . the creep rupture ductility of the AM material was significantly reduced at all testing conditions. Secondary ion mass spectrometry (SIMS) revealed that sulfur .

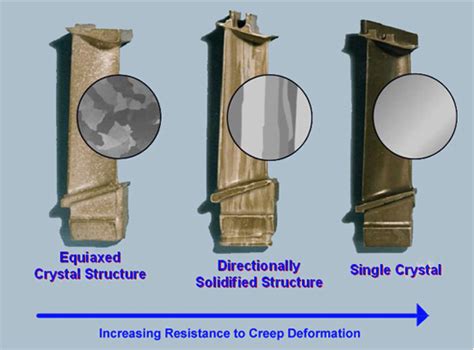

In general, the material will creep from low temperature to near the melting point, T m, . also found, in their study on the high-temperature creep mechanism of TC6 alloy, that there are different creep mechanisms at different temperatures. The OM and TEM techniques were used to observe and analyze the microstructure of the alloy before and . Ni-based disk superalloys are an important class of high-temperature structural materials that are primarily utilised for critical hot section engine components in aircraft gas turbine engines. . The single-crystal tests provide new insight into grain orientation effects on creep response and deformation mechanisms. Creep at lower . low temperature (L T) creep at 0. 3–0. 5 T L and high temperature (HT) creep at 0. 5– 0 . 9 T L . Higher temperatures are related to other mechanisms and should be presented The deformation rate at the stationary stage defines the creep strength of a material. The materials used in high-temperature applications should have high corrosion resistance, oxidation resistance, and creep strength.

The quest for stronger and tougher structural materials is challenging because of the mutually exclusive nature of strength and ductility (Brechtl et al., 2019; Jiang et al., 2023) .Furthermore, the complexity of materials selection and design increases for high-temperature applications like future turbine engines and hypersonic vehicles, where materials are .

Materials Science and Engineering: A. Volume 786, 1 June 2020, 139414. . High temperature creep mechanisms in single crystals of some high performance nickel base superalloys. High Temperature Alloys (1987), pp. 9-18. Crossref Google Scholar [20] A. Epishin, T. Link, U. Brückner, P.D. Portella. This study investigates the high-temperature creep behavior of a novel (Fe 50 Mn 30 Co 10 Cr 10) 91 Al 9 non-equiatomic high-entropy alloy (HEA) spanning the temperature range of 873–973 K and stress conditions from 50 to 90 MPa. Microstructural examinations and theoretical analyses are conducted to elucidate the performance parameter and deformation .Diffusional creep is a mechanism that occurs in materials where the movement of atoms through the crystal lattice is the primary source of deformation. In this mechanism, atoms move from areas of high stress to areas of low stress, causing the material to deform over time. . Use materials with high melting temperatures.

Creep Deformation Definition: The progressive, time-dependent deformation of materials under constant stress, often occurring at high temperatures. Creep Deformation Mechanism: Includes dislocation movement, grain boundary sliding, and diffusion of atoms, affecting materials' long-term behavior under stress.

The creep properties of the composites exceed those of matrix alloys. The steady-state creep rate of 7055 Al alloy is 9.7–22.9 times that of a composite with a particle volume fraction of 3vol%. The results show that ZrB 2 and Al 2 O 3 particles can improve the creep properties of the material at high temperature. (2)

The mechanisms of creep deformation and damage in reactor pressure vessel (RPV) material, however, become complicated since RPV experiences a synthetic effect of ultra-high temperature (above the phase transition temperature), high temperature gradient and high stress gradient under IVR condition [7,8,9]. Investigations on the mechanical . Tensile tests were conducted on 15-15Ti and 15-15Ti-Y steels in air at 200–700 °C. The strain rates employed was and 1 × 10-4 s −1 at temperatures ranging from 200 to 700 °C. The tensile specimens used in the tests had an average grain size of 16.7 and 16.4 μm, and were obtained from the plates after annealing.This set of Engineering Materials & Metallurgy Multiple Choice Questions & Answers (MCQs) focuses on “Mechanisms of Creep & Creep Resistant Materials”. 1. Creep occurs at a temperature above _____ a) 0.16 T m b) 0.22 T m c) 0.4 T m d) 0.91 T m View Answer

P92 steel is widely used in ultra-supercritical units due to its excellent high-temperature performance. This paper studies the microstructure of P92 steel steam pipes in three conditions: as-supplied, after 80,000 h of service at 67.06 MPa stress, and after 100,000 h of service at 80.28 MPa stress. After prolonged service, the P92 steel retains its martensitic . These phenomena have been incorporated into ‘damage interaction diagrams’ which feature in many high temperature Code cases (ASME, R5, RCC-MR etc.). Fractional creep and fatigue damage are considered separately, and failure is conceded when their sum is unity (‘additive’ mode). For some materials the sum is set to a value <1. Mechanical Properties of SiC F /SiC Composites with ZrSiO 4 Interphase at a High Temperature (Pages: 205-210) Y. Tanaka, Y. Inoue, N. Miyamoto, M. Sato, . CMC Creep Mechanism under Argon (Pages: 492-497) . Short Fibre Reinforced CMC Materials for High Performance Brakes (Pages: 809-815) B. Heidenreich, R. Renz, Dr. W. Krenkel, Summary; .

what is creep resistant to

coefficient friction tester

coefficient of friction test fixture

Resultado da 15 de fev. de 2024 · Descargar el APK de Versión de prueba de Minecraft 1.20.62.02 par Android ahora. Sin costes extra. Valoración de los usuarios .

mechanism of creep of material at high temperature|what is creep resistant to